Agriculture drones equipped with pesticide spray nozzles are revolutionizing farming practices worldwide, offering a high-tech solution for crop protection. As global demand for food escalates, these drones are not just an innovation. They are becoming a necessity, projected to significantly impact the agriculture drone market by 2030. With their ability to apply both dry and liquid pesticides efficiently, alongside collecting vital crop data, drones enhance farming efficiency and safety by navigating challenging terrains and minimizing applicator exposure to chemicals.

When considering pesticide application, the choice of spray nozzle types, such as brass nozzles, flat-fan nozzles, and hollow-cone nozzles, becomes critical for optimizing spray distribution, droplet size, and overall application efficiency. Factors requiring careful consideration include spray volume, quality, and the technology behind various water spray nozzle types, which all play a significant role in achieving targeted pest control while adhering to sprayer calibration guidelines. The advent of new nozzle designs, like those with feedback channels created using 3D printing technology, promises advancements in spraying performance, offering smaller, more uniform droplet sizes compared to traditional nozzles.

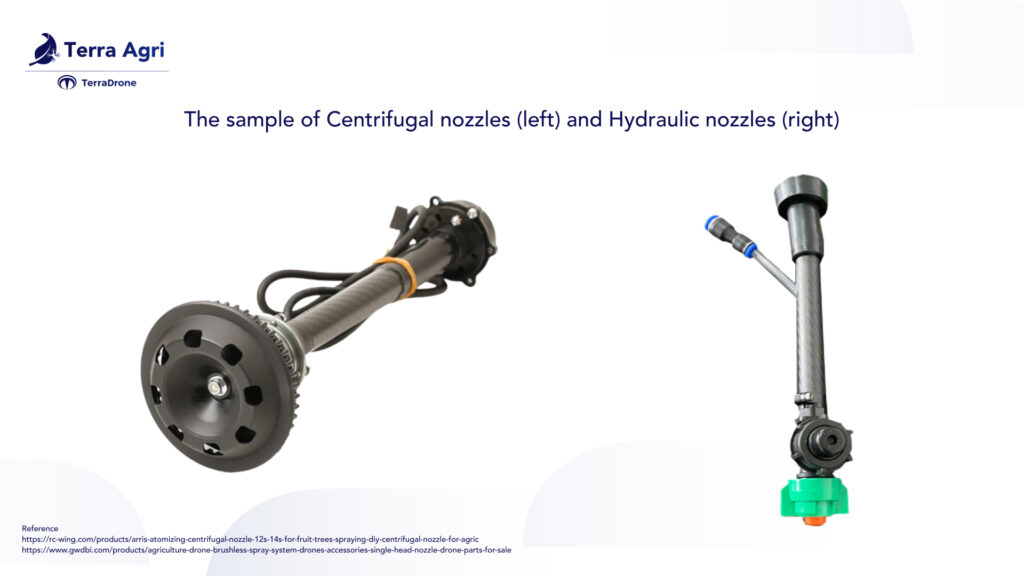

Comparison: Pressure Nozzles vs Centrifugal Nozzles

Pressure Nozzles in Agriculture Drones

Designed to produce a hollow, fan-shaped spray with a 90-degree angle, pressure nozzles are adept at handling a range of pesticides and fertilizers. They’re compatible with 20mm carbon fiber tubes on agricultural UAVs, offering easy installation and a quick connection feature. Their lightweight design doesn’t add significant weight to drones, maintaining flight efficiency.

These nozzles excel in water-saving, which translates to pesticide savings and enhanced spraying efficiency. They operate effectively between 20 to 50 PSI, covering a wide range of agricultural spraying needs. Specifically recommended for insecticides requiring 10-50μm spray droplets, they are ideal for crops like palm trees and plantains. Their strong downward pressure ensures deep penetration into plants with minimal drift, even in hot and dry conditions.

This design simplicity, coupled with cost-effectiveness, positions pressure nozzles as a go-to choice for agricultural drone spraying, particularly for high-bole plants and in conditions where drift and evaporation are concerns.

Centrifugal Nozzles in Agriculture Drones

Centrifugal nozzles in agriculture drones offer a sophisticated approach to spraying, especially for crops requiring fine and uniform application, like rice, wheat, and fruits. These nozzles leverage the power of centrifugal force, which is generated by motor rotation, to atomize liquid into tiny, uniform droplets. The size of these droplets is primarily determined by the motor’s voltage, ensuring a precise application suited to the needs of specific crops and pesticides.

However, the complexity and cost of centrifugal nozzles can be higher than other types, with potential challenges such as motor issues and uneven liquid distribution. Despite these challenges, their ability to control spray flow and droplet size remotely makes them a valuable tool for precision agriculture.

Ideal Situations for Each Nozzle Type

Identifying the perfect scenario for each type of nozzle during drone spraying operations is crucial for maximizing efficiency and effectiveness in pesticide application.

Cone Nozzles

Cone nozzles are optimal for varied crop types. Especially beneficial for crops requiring thorough coverage, cone nozzles enhance spray dispersion, ensuring that pesticides reach every part of the plant.

Flat Fan Nozzles

A study highlighted that flat fan nozzles, when set at a 62.24° angle and operated at a height of 600 mm with a pressure of 6 kg/cm^2, delivered the most efficient spray distribution. This setup produced the optimum spray volumetric distribution and the lowest coefficient of variation, making it ideal for situations requiring precise application and uniform coverage across the crops.

Understanding these specific conditions and adjusting your drone spraying strategy accordingly can lead to significant improvements in pesticide application efficiency. Whether dealing with dense foliage requiring deep penetration or broad-acre crops needing uniform coverage, selecting the right nozzle based on these guidelines can make a substantial difference in your agricultural drone operations.

FAQs

For the application of pesticides, hollow-cone nozzles are typically recommended. These nozzles are particularly effective for applying insecticides or fungicides to field crops where it’s crucial to penetrate foliage and achieve thorough coverage of the leaf surface. They are designed to operate at pressures ranging from 40 to 100 psi.

In agricultural spraying, the most frequently used nozzle types for ground application of chemicals include flat-fan, even flat-fan, and cone nozzles. Regular flat-fan nozzles are the go-to choice for the broad application of herbicides and for applying certain insecticides where deep foliar penetration and extensive coverage are not necessary.

Drone spraying offers several advantages over traditional manual spraying methods. It can save up to 90% of water and reduce the usage of agrochemicals by about 23%. Additionally, drone spraying is more effective in covering the undersides of leaves, whereas manual spraying tends to deposit chemicals on the tips of leaves, resulting in significant dripping and wastage.

For pesticide application, cone nozzles are a suitable option. There are two main varieties: hollow cone nozzles, which produce a ring-shaped pattern of finely atomized spray ideal for high-pressure applications, and full cone nozzles, which generate a full circular pattern of coarser droplets. Additionally, streaming nozzles, which produce several solid streams of liquid, are more suitable for liquid fertilizer applications.