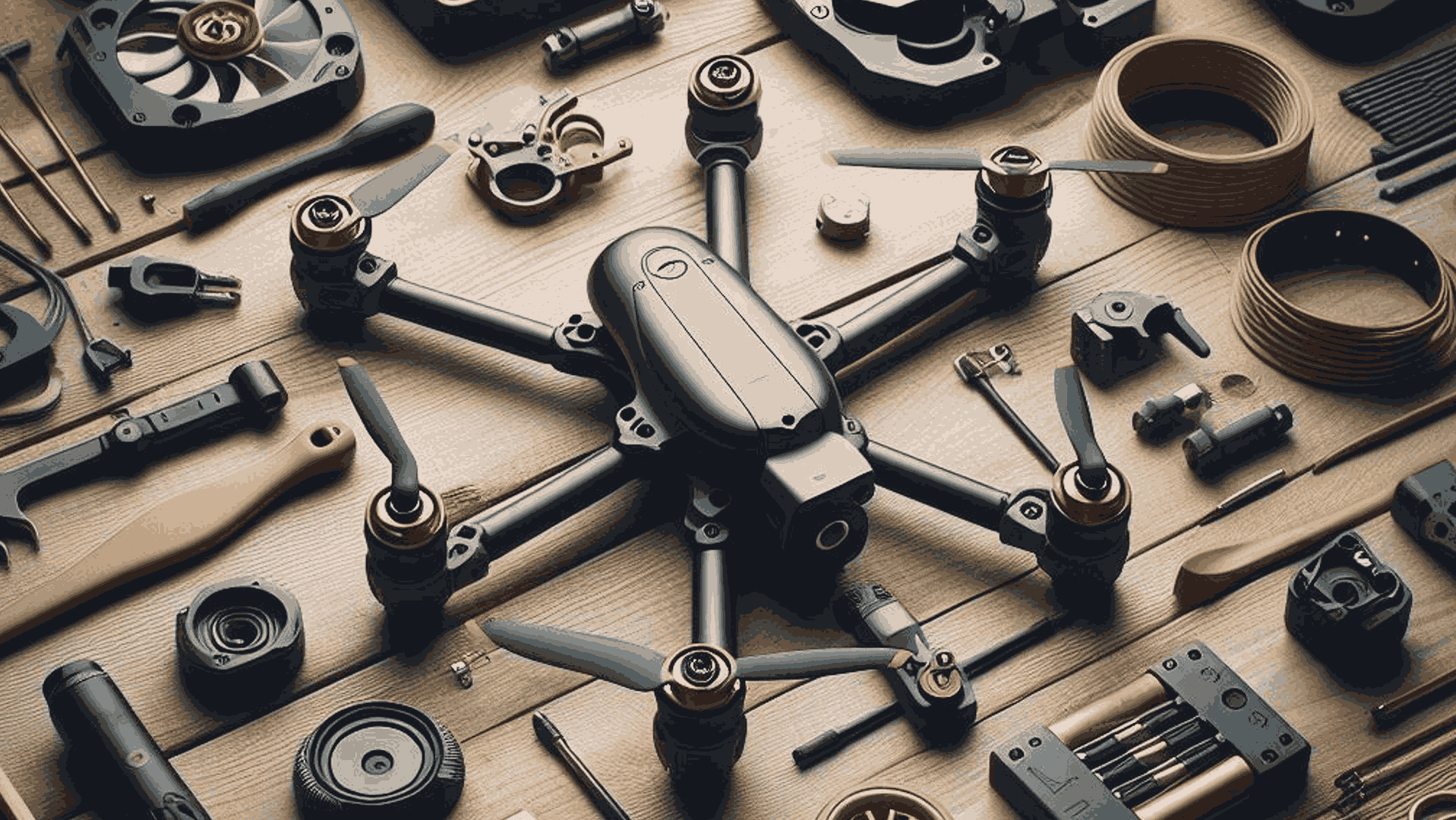

Are you contemplating a career in an agriculture drones company ? Whether you are steering them or maintaining them, understanding the key drone parts is pivotal. This comprehensive guide will delve into 7 more essential drone components used in farming, unraveling their functions and offering insights into proper care and maintenance.

The basic components of a drone

Structural Integrity: Frame and Body

At the heart of every agricultural UAV (Unmanned Aerial Vehicle) or drone is its structural integrity, provided by the frame and body. These elements form the essential foundation for consistent and trustworthy aerial maneuvers. Constructed from robust yet lightweight materials such as carbon fiber or aluminum, these frameworks offer resilience to diverse climatic challenges. Their design facilitates precise navigation above extensive agricultural domains.

A Pair of Propellers and Motors

Propellers and motors collaborate as the harmonious pair that propels agricultural drones with finesse and accuracy. Top-tier motors, when combined with state-of-the-art propulsion systems, impart the necessary force to bear significant payloads and traverse varied landscapes. This union of technology enables drones to function fluidly within the dynamic sphere of modern agriculture.

Endurance Batteries and Power Systems

The batteries and power systems are the endurance enablers of agricultural UAVs, critical to their ability to span large expanses of farmland. The dependability of a UAV’s flight capacity is anchored in the performance of lithium-ion batteries, noted for their superior energy density and extended service life. Alongside advanced power management systems, these UAVs are optimized for energy efficiency, which prolongs their operational duration and allows for more extensive agricultural surveying in one journey.

GPS Navigation

The intricacy of navigating expansive agricultural fields is masterfully addressed by sophisticated GPS navigation systems. This technology guarantees precise positioning and enables detailed field mapping, allowing drones to adhere to pre-set aerial routes. GPS integration is instrumental in reducing collision risks and amplifying overall efficiency, granting an overarching perspective of farm layouts.

Sensors and Imaging Systems

Integral to the drones toolkit are the sensors and imaging systems, which are pivotal in gathering actionable intelligence. These advanced instruments collect essential data on crop vitality, soil conditions, and plant health. Technologies like multispectral and thermal cameras, along with LIDAR, equip agronomists with the means to track crop development, identify disease outbreaks, and pinpoint areas needing urgent intervention.

Additional Drone Parts: Payload

Taking precision agriculture to the zenith, select agricultural drones are outfitted with a payload release mechanism. This innovative attribute empowers drones to transport and accurately deploy fertilizers, pesticides, or seeds. By concentrating on particular zones or crops needing treatment, this mechanism drastically reduces resource wastage and enhances the efficacy of farming protocols.

Data Processing and Analysis Software

Data processing and analysis software is one of the drone parts which doesn’t install in the drone body. Yet the tool will transform all data captured by drone. These platforms leverage advanced algorithms and machine learning to transmute raw aerial data into practical guidance. Armed with comprehensive analytical reports, farmers are positioned to make strategic decisions that enhance crop yield and efficiency.

Remote Control Units and Ground Control Stations Command Agricultural Drones

Farmers exercise precise control over agricultural drones using remote control units and ground control stations. These tools enable them to pilot the drones, fine-tune settings, and observe real-time data effortlessly. Meanwhile, communication systems such as Wi-Fi and cellular networks ensure swift and reliable data exchange between drones and ground controllers, creating a seamless flow of information.

Safety Features Guard Agricultural Drone Operations

To ensure safe drone operations in agriculture, manufacturers equip each drone with advanced safety features. Obstacle detection systems actively prevent collisions, fail-safe mechanisms engage during critical failures, and return-to-home functions guide drones back safely. These integrated safety protocols protect the drones from accidents, securing the investment in agricultural technology.

Weatherproofing Enhances Drone Performance in Diverse Conditions

Particular drone parts must perform reliably across various weather conditions. To achieve this, manufacturers or agriculture drone providers will implement weatherproofing measures that protect electronic components, secure connectors, and use waterproof materials. These enhancements extend the agriculture drones’ operational life and maintain consistent performance whether facing rain, wind, dust, or extreme temperatures.

Conclusion

The continuous evolution of agricultural drone parts marks their transition from mere technology to indispensable tools in agriculture. Sturdy frames, efficient propellers, sensitive sensors, and advanced software all contribute significantly to improving farming methods. These components not only optimize crop yields but also support the advancement of sustainable agricultural practices.

FAQ Related to Agriculture Drones Components

Well, it’s a bit like asking how long a car can run before it needs more gas – it depends. If your drone is lightweight, not carrying much, and the weather’s good, you can expect it to fly around for about 20 to 30 minutes. Just enough time to take a good look at your fields or herds..

Agricultural drones, equipped with advanced sensors including cameras, multispectral, hyperspectral, and GPS systems, play a crucial role in gathering valuable data from the fields. These sensors act as the drone’s eyes and ears, capturing information about crop health, soil conditions, and more. Initially, the data collected by these sensors is stored onboard the drone itself.

Once the data collection process is complete, the drone becomes like a messenger. It transmits this valuable information to connected servers. The method of transmission depends on the drone’s capabilities and the available technology. Sometimes it uses Wi-Fi, similar to how we connect our devices at home. In other cases, it relies on cellular data networks, just like our phones do when we’re out and about. And in remote or expansive areas, it might even communicate via satellite links.

A noticeable decrease in flight time is a clear sign that the battery’s capacity has diminished, indicating it can no longer efficiently meet the operational demands of the drone. Extended charging periods also suggest a decline in the battery’s ability to store power, signaling a potential nearing end of its service life.

Additionally, if the battery generates excessive heat during operation, it could signify a compromised integrity and an approaching end of its lifespan. These signals underscore the importance of vigilant monitoring to uphold the reliability and productivity of your agricultural drone operations.