Are you interested in agricultural drones? Well, drones can be expensive, especially the ones used for farming, like spraying drones, mapping, and garden inspections. The cost of these drones depends on their features and the payload they carry. The more advanced the drone, the higher its price will be.

But the cost of the drone is only one part of the equation. Knowing how to take care of your agricultural drone is essential to ensure its long lifespan. Proper maintenance and care can help you get the most out of your investment. Here are seven agriculture drone maintenance checklist for long life

7 Maintenance Steps for Prolonging Drone Lifespan

Make Sure to Clean the Motors Thoroughly

Keeping your drone’s motors clean ensures its longevity and performance. Dust, sand, grass, or dirt can quickly accumulate inside the motors, potentially leading to overheating or reduced efficiency. Regular maintenance includes gently cleaning the motors with a soft brush to remove debris. For a more thorough cleaning, consider using isopropyl alcohol to dissolve dirt effectively without causing damage. Additionally, wiping down the body of your drone with a clean, damp towel helps maintain its overall cleanliness and appearance.

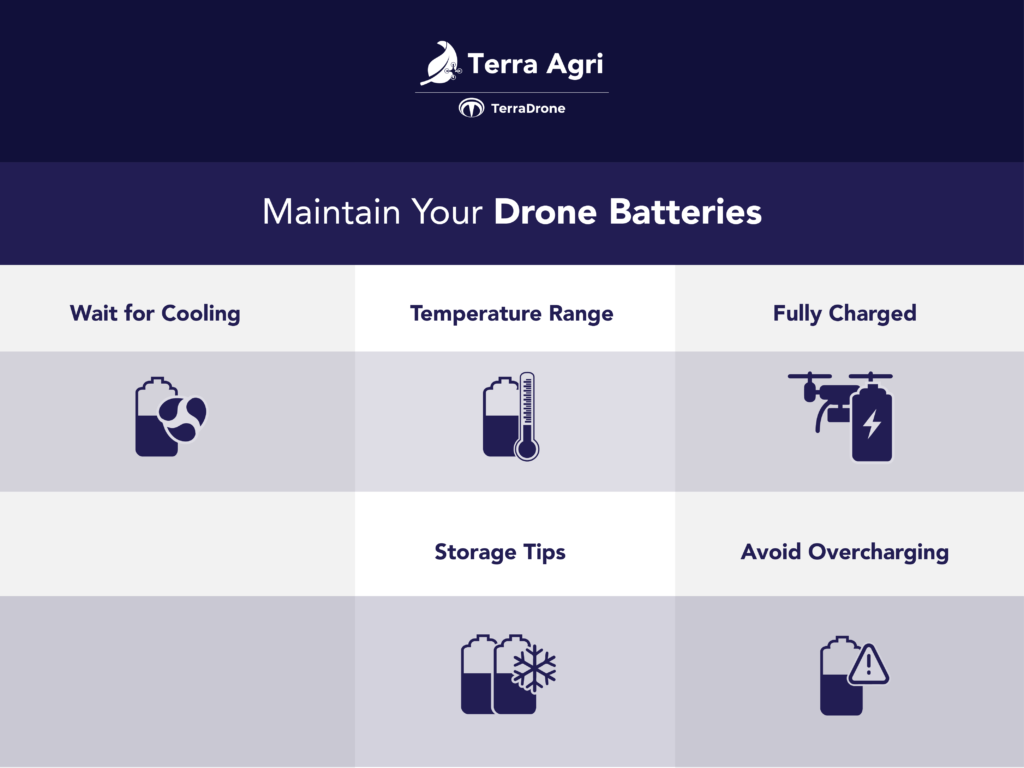

Maintain Your Drone Batteries

Taking good care of your drone’s batteries is vital to ensure safety and the best possible performance. Here are some essential tips to keep in mind:

– Wait for the battery to cool down before charging it after a flight, as setting it while it’s hot can cause damage.

– Always charge your batteries within the recommended temperature range to prevent overheating and other problems.

– It’s best to fly with fully charged batteries to ensure maximum flight time and performance.

– Store your batteries in a cool, dry place when you’re not using them to protect them from humidity and extreme temperatures.

– Don’t overcharge or charge your battery too quickly, as this can harm the battery.

So, When Should I Replace the Agriculture Drone Battery?

Taking proper care of your drone’s batteries ensures their longevity and optimal performance. However, as with any electronic device, there might come a time when you need to replace your drone’s battery. Therefore, it is vital to know the signs that indicate a need for battery replacement.

One of the most obvious signs you need to replace your agriculture drone battery is if you notice any leaking, damage, or visible swelling. These signs indicate that the battery is damaged and is no longer safe. Additionally, if you receive a battery cell damage notification from the app, you should replace the battery immediately.

Suppose you notice battery errors on your drone, even after conducting standard charge and discharge operations. In that case, the battery is not in good condition and requires replacement.

Conduct Aerial Drone Maintenance Schedule

Another drone maintenance checklist is conducting agriculture drone maintenance flights. These flights allow operators to identify potential issues, detect problems such as malfunctions or decreased efficiency, and make necessary adjustments or repairs to maintain equipment reliability and performance.

Moreover, regular flights allow operators to assess drone conditions, verify functionality, and monitor behavior and performance in real-world situations. Operators can ensure the equipment’s longevity and overall maintenance by doing so.

What Is the Recommended Frequency for Maintaining Agriculture Drones by Flying Them Regularly?

It is essential to conduct regular aerial drone maintenance flights to ensure the drone functions correctly. The frequency of these flights may vary based on the type of drone and the specific circumstances of its usage. However, conducting routine maintenance flights to identify and rectify problems before they escalate is crucial for ensuring optimal performance and longevity.

For heavily used drones, it is suggested to have checkups and servicing every 12 months or more often to increase the lifespan of battery packs. Incorporating regular maintenance flights into the drone’s operational schedule is essential for maximizing its benefits and ensuring safe and effective use in agricultural applications. Regular maintenance flights provide the drone’s longevity and peak performance, although specific time intervals may not be universally defined.

Keep Software Up to Date

It’s essential to keep your drone’s software up to date to ensure it performs well and is safe to operate. Manufacturers regularly release updates to fix problems, add features, and improve overall functionality. Flying with outdated firmware can limit your drone’s capabilities and pose risks during flight. Before each flight, check for and install the latest updates to ensure a smooth and safe flying experience.

Inspection Before and After Each Flight

Before and after each flight, inspect the drone. Check screws, components, connectors, and battery plugs. Inspect propulsion, spray, and power systems for damage or wear. A pre-flight drone servicing checklist should include these critical components:

Safety Kit

It’s essential to have a safety kit with an anemometer, fire extinguisher, hard hat, hi-viz vest, safety goggles, first aid kit, collapsible safety cones, and heavy-duty holdall when flying a drone.

Environment and Weather Check

Before lifting off, thoroughly check your surroundings for overhead wires, towers, cables, and other potential obstacles or hazards that may affect your flight. Also, keep an eye on the weather and wind direction before flying.

Equipment

Performing a pre-flight inspection checklist is highly recommended to ensure that your drone is in excellent condition before takeoff. To get started, check for cracks, damage, or loose wiring. Ensure your batteries are fully charged, and thoroughly inspect your transmitter.

Takeoff Preparation

Undertake a range test and check your camera settings before you fly. Every flight should begin with a short hover test for around 30 seconds. Hover your device 5 to 6 feet from the ground to ensure everything works OK.

Emergency Planning

It is essential to have emergency planning steps pre-prepared. Make sure to carry a working, fully charged mobile phone with you at all times. Additionally, inform someone about your whereabouts and expected return time.

Notifications and Permissions

Before flying your drone, ensure you have obtained all the necessary permissions and notifications.

So, How Long Does It Typically Take to Complete a Pre-Flight Checklist for Agriculture Drones?

The time it takes to complete a pre-flight checklist for agriculture drones can vary depending on the checklist’s complexity and the pilot’s experience. However, a typical pre-flight checklist for agriculture drones can take 10 to 30 minutes to complete. It is essential to take the time to complete the checklist thoroughly to ensure the safety and success of the drone operation. Rushing through the checklist or skipping steps can lead to accidents, equipment damage, and legal consequences. By completing a comprehensive pre-flight checklist, pilots can mitigate risks and ensure safe and successful drone operations in agriculture.

Calibrate Sensors to Ensure Accurate Data Collection

Calibrating sensors are crucial maintenance tasks for agriculture drones to ensure accurate data collection. Additionally, during calibration, a baseline is established for the drone’s internal sensors to ensure they are in sync with its physical conditions and orientation. This process includes adjusting the sensors or calibrating the compass to ensure accurate readings. It is crucial to calibrate the barometer, lidar, radar, sonar, thermal, and multispectral sensors to ensure accurate readings and optimal performance. In fact, calibration is essential to ensure that the drone’s internal sensors function correctly and provide reliable data.

Regular sensor calibration is essential as it helps maintain the accuracy and reliability of the drone’s readings, especially in critical applications such as surveying, mapping, or environmental monitoring. Calibration tools required for drone calibration include a computer or mobile device, a USB cable, and specialized calibration software. Following best practices in sensor calibration is crucial to obtain reliable and consistent data from the drone. And don’t miss this drone maintenance checklist step.

Inspecting the Spray System

Last but not least, the drone maintenance checklist you need to keep in mind is inspecting the spray system. The spray system comprises the pump, tank, and connectors delivering crops agrochemicals. During inspection, examining the pump and tank for any signs of wear and the connectors for any looseness or corrosion is crucial:

1. The pump and tank wear can lead to decreased efficiency and performance.

2. Flexible connectors can damage the drone and cause leaks. Therefore, it is vital to check the wear of the pump and tank, ensuring that they are in good condition. Similarly, it is necessary to examine the connectors for any looseness or corrosion and fix them immediately if found.

3. By reviewing the spray system regularly, operators can guarantee that the drone delivers agrochemicals accurately and efficiently, contributing to the agricultural operation’s overall success.

Conclusion

Maintaining your agriculture drone is crucial for its optimal performance and longevity. Just as you would care for any valuable tool, regular maintenance ensures that your drone operates efficiently when needed. Each step plays a vital role in ensuring a successful operation, from cleaning its motors to monitoring its batteries. Therefore, it is essential to prioritize the care of your drone, as it will repay you with reliable performance and extended service life, ultimately benefiting your agricultural endeavors.